The expertise of Foissy machining

Since its origin is Foissy machining (first of its own gross forge and those of its parent, then as a subsidiary usinier) Foissy today has acquired great expertise in this field.

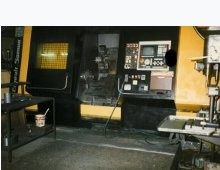

Foissy combines the use of conventional equipment and numerical control.

Some of the material is moved : although usually working in small batches, each time Foissy trying to recreate a production machine and around the largest, a "island of manufacture".

Quality of Foissy door special attention to the activity of machining learn more

The main materials are :

- centre usinage horizontal

- brocheuse

![-]() 2 Horizontal machining centers

2 Horizontal machining centers

![-]() 1 stapler

1 stapler

![-]() 4 CNC lathes (max. opening 500)

4 CNC lathes (max. opening 500)

![-]() Several drills multipin some with turntable

Several drills multipin some with turntable

- tour vertical bi broche

- Tour à décolleter

![-]() 1 double vertical lathe

1 double vertical lathe

![-]() 2 laps Topping

2 laps Topping

- centre de parçage

- fraiseuse

![-]() 3 vertical hole centers (one with a divider turner)

3 vertical hole centers (one with a divider turner)

![-]() Milling

Milling

![-]() Vertical and horizontal drills called "the meeting" (especially for hinges)

Vertical and horizontal drills called "the meeting" (especially for hinges)

![-]() Tapping of the

Tapping of the

![-]() 1 grinder by diving

1 grinder by diving

![-]() Conventional lathes

Conventional lathes

![-]() Boring machines

Boring machines

Beyond the machining Foissy to ways to :

![-]() Specific controls (magnaflux)

Specific controls (magnaflux)

![-]() Hardening of the HF,

Hardening of the HF,

![-]() Additional operations (welding, assembly, etc.).

Additional operations (welding, assembly, etc.).

Achievements Foissy machining :

Foissy fact of machining :

![-]() As a subcontractor for gross machining service blacksmiths and smelters service or user customers or from raw material (steel, stainless steel) : learn more

As a subcontractor for gross machining service blacksmiths and smelters service or user customers or from raw material (steel, stainless steel) : learn more

![-]() As integrated means for the production of parts in wire, bars, or profile pieces welded (production of axes, finishes, etc.).

As integrated means for the production of parts in wire, bars, or profile pieces welded (production of axes, finishes, etc.).

Back to Welcome - Presentation - Sitemap - Means of production - Contact

Back to Top

For further information, contact us :

* Tel. : 33 (0) 3 24 52 65 65 * Fax. : 33 (0) 3 24 37 79 90 * Email : contact@foissy.com *